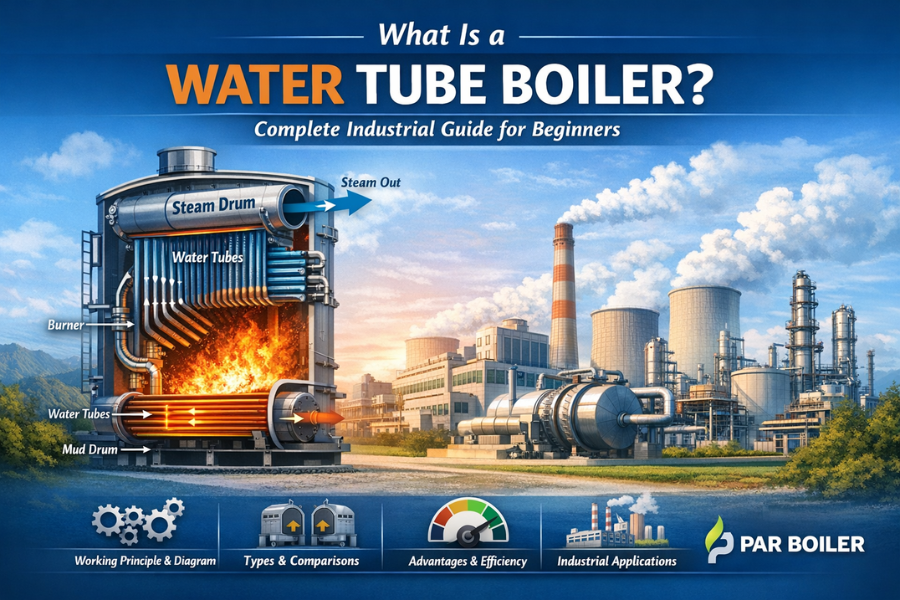

A water tube boiler is one of the most widely used steam-generating systems in modern industries. It is specially designed for high-pressure and high-temperature applications, making it ideal for power plants, refineries, chemical industries, and large manufacturing units.

In this complete beginner-friendly guide, you will learn about the water tube boiler working principle, construction, parts, operation, types, advantages, efficiency, comparison with fire tube boilers, and industrial applications.

What Is a Water Tube Boiler?

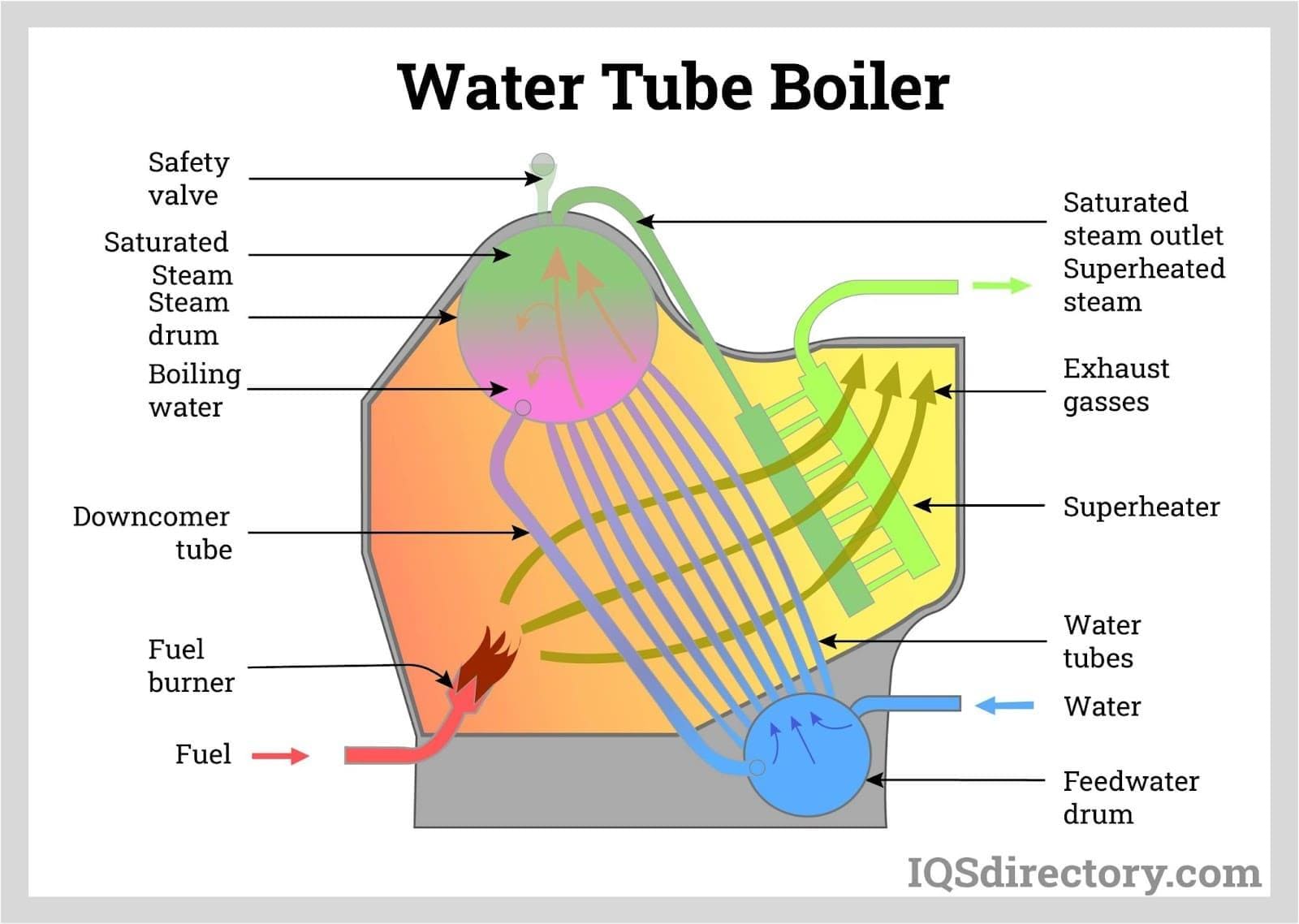

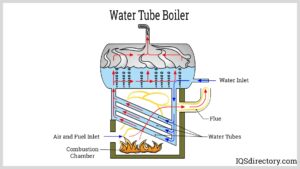

A water tube boiler is a type of steam boiler in which water flows inside tubes, and hot combustion gases flow outside the tubes. Heat from the flue gases transfers through the tube walls to convert water into steam.

Unlike fire tube boilers, this design allows the boiler to operate at very high pressures, which is why it is commonly used as a high pressure water tube boiler in industrial settings.

Water Tube Boiler Working Principle

The water tube boiler working principle is based on heat transfer through convection and conduction.

-

Water enters the steam drum.

-

It flows through tubes connected to the drum.

-

Hot gases from fuel combustion surround the tubes.

-

Heat transfers to the water.

-

Water converts into steam.

-

Steam rises back into the drum and is supplied for industrial use.

This simple yet powerful process explains how does a water tube boiler work in industry — it continuously generates steam under high pressure for large-scale operations.

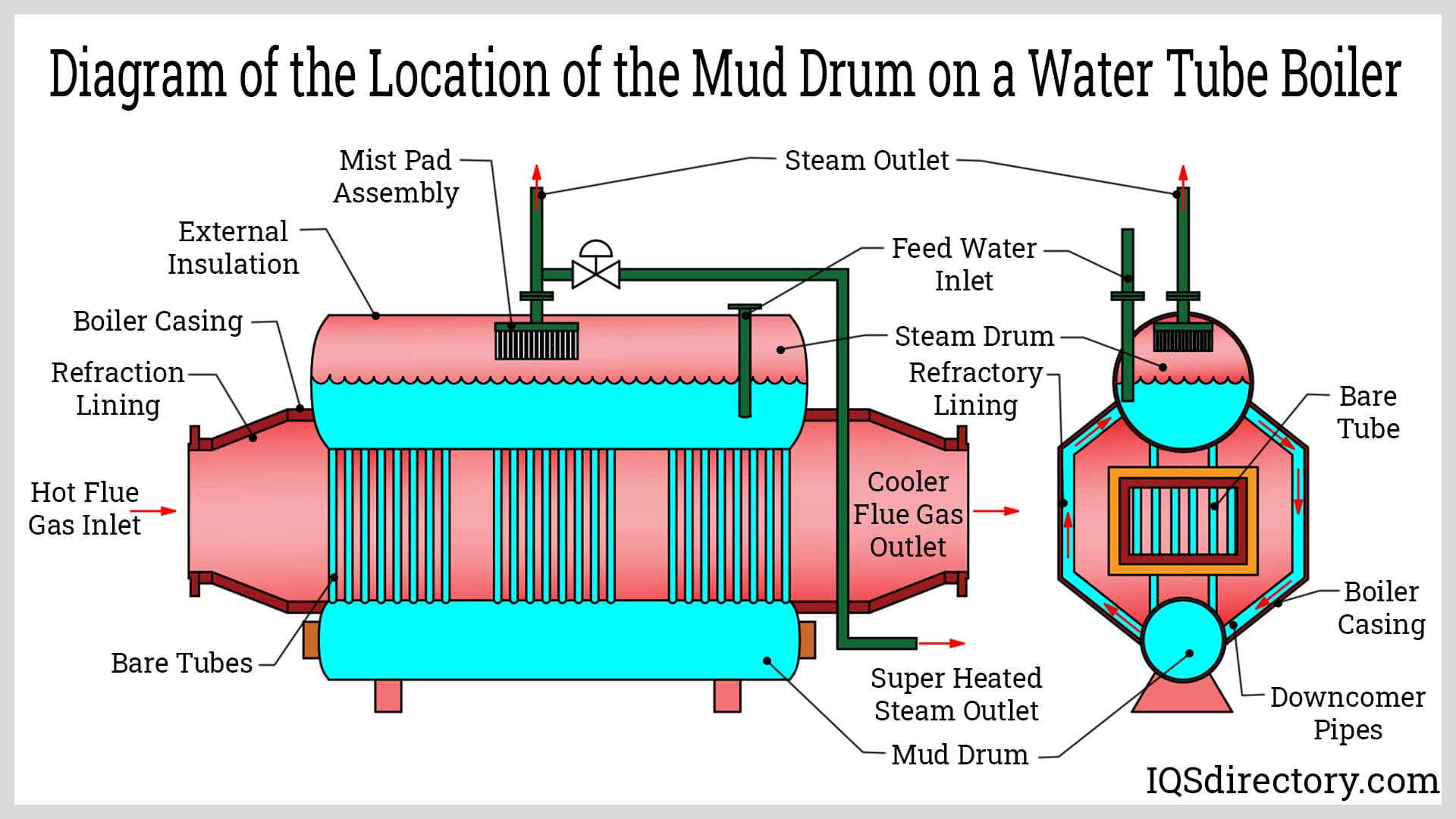

Water Tube Boiler Diagram

A bent tube water tube boiler uses curved tubes for better heat absorption. It is widely used in power plants and large industries.

2. Straight Tube Water Tube Boiler

A straight tube water tube boiler contains straight tubes connected to drums. It is easier to clean and maintain.

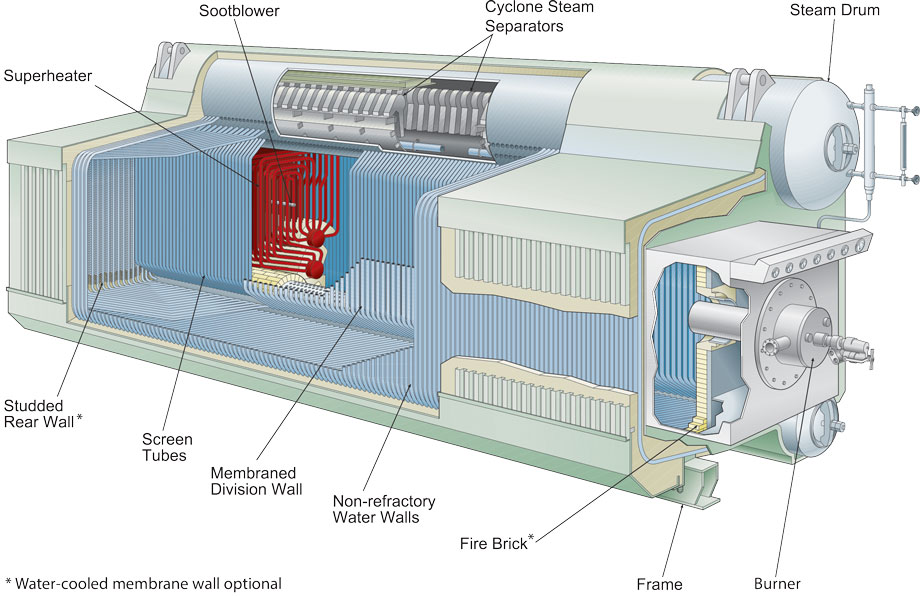

3. Babcock and Wilcox Water Tube Boiler

The Babcock and Wilcox water tube boiler is one of the earliest and most famous designs. It uses inclined tubes and is commonly found in power stations.

4. Stirling Water Tube Boiler

The Stirling water tube boiler features multiple drums and is suitable for large steam demands.